Publisher’s preface: Every morning we’re inundated with sensationalized accounts of events that are presented as news when, in fact, these accounts are accusing diatribes built on finger-pointing and fact-omissions. We’re digesting our morning coffee along with emotionally charged rants created to serve the agendas of those who prepare them, rants that turn the front page into the editorial page.

Too often the target is the U.S. Oil & Gas Industry, the industry that’s worn a BULLSEYE on its back for the last few decades while, ironically, providing the country’s economy with one of the most important elements for growth: low-cost energy. However, since we at the Bakken Oil Business Journal know the U.S. Oil & Gas Industry is the industry that opens the door to increasing the prosperity of the US more than any other, I present you with something real, an account of some hard-working folks who are showing the world why the US is the greatest country in the world, why it is the land of the free and home of the brave.

By: Marissa van der Valk

Travis Cooksey is the Safety Coordinator for Continental Resources in North Dakota and Montana. He performs safety inspections on workover rigs, drilling rigs and well sites. His overall duties include finding ways to keep the men and women out of harms way in the Bakken oil patch.

Travis Cooksey is the Safety Coordinator for Continental Resources in North Dakota and Montana. He performs safety inspections on workover rigs, drilling rigs and well sites. His overall duties include finding ways to keep the men and women out of harms way in the Bakken oil patch.

How does a California surfer end up in the oil fields of North Dakota? The simple answer could be that he drove there, but life’s journey wasn’t so simple. It involved biotechnology, the US Navy, a pregnant wife, a fifth wheel and the love of family and country.

Travis Cooksey was born in Redondo Beach, California located in Los Angeles County, which is known for its white sandy beaches and spectacular surfing. Travis is the baby in a family of four boys. He spent his formative years in Camarillo, California, a suburb 45 miles north of Los Angeles. He was a state ranked 800 meter runner in high school and qualified for Nationals in his senior year. After high school, Travis first jobs were as a pool cleaner and asbestos remover.

He was first introduced to surfing about 20 years ago through a neighbor turned best friend Leroy, who gave him a wetsuit and surfboard for his birthday. Travis describes this gift as the gift that kept on giving. He started surfing and fell in love with catching the next big wave.

In 1990, Travis was hired to work at bio-technology company Amgen Inc located in Thousand Oaks, California. For the next 13 years Travis worked as a lab technician in the human genomics laboratory. His coworkers describe Travis as being a hard worker with a penchant for telling hilarious stories. He was also described as being fiercely loyal to his family and his country. This is why at 34 years old Travis decided to join the US Navy.

In 1990, Travis was hired to work at bio-technology company Amgen Inc located in Thousand Oaks, California. For the next 13 years Travis worked as a lab technician in the human genomics laboratory. His coworkers describe Travis as being a hard worker with a penchant for telling hilarious stories. He was also described as being fiercely loyal to his family and his country. This is why at 34 years old Travis decided to join the US Navy.

Travis enlisted in the Navy in 2003 at the ripe old age of 34 just one year away from the cut off age. And his decision to enlist was triggered by the tragic events on September 11, 2001. He joined through the Navy’s Delayed Entry Program (DEP) which is a program designed to give the recruit some time to get their life in order before going to boot camp. Travis describes his time in boot camp as ‘not an easy time’.

The training instructors tended to be harder on recruits who were over thirty years old. Travis describes himself as a highly dedicated loyal American with a heart full of patriotism so even though boot camp was difficult, no one was going to stop him from reaching his goal to succeed.

Travis went into the Navy as a reservist, but right after graduation from hospital corps school he received THE letter from President Bush putting him on full active duty status. He was first stationed at Great Lakes in Illinois and then was stationed in Port Hueneme, California. He also spent time at Camp Pendleton and ended his military career at Point Mugu. He was attached to shore duty hospitals and squadrons with service to the special E.O.D. (explosive ordinance disposal) unit.

He received three NAM’s (Navy Achievement Medal) awards. Travis had a tough time finding work in California, Oregon and Washington six months prior to being released from active duty. And after 8 years in the US Navy Travis was faced with a decision, re-enlist for another tour of duty or go to work for the brother of his Navy Chief, who was hauling crude oil in Williston, North Dakota.

The US Navy’s loss was the Bakken’s gain when Travis decided to take the job in the booming oil patch of North Dakota. He was honorably discharged as a Petty Officer Second Class (PO2).

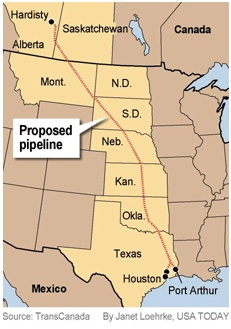

Travis is the father to four sons: Brandon 22, Braydon 12, Tayln 5, Pacey 2, and he and his wife Michelle are currently expecting their first daughter in July. He moved to Williston in October of 2011. He and Michelle, who was pregnant with Pacey at the time of making the move to North Dakota, loaded up their fifth wheel and took Talyn and their dog on the 1,600 mile drive to Williston.

Travis is the father to four sons: Brandon 22, Braydon 12, Tayln 5, Pacey 2, and he and his wife Michelle are currently expecting their first daughter in July. He moved to Williston in October of 2011. He and Michelle, who was pregnant with Pacey at the time of making the move to North Dakota, loaded up their fifth wheel and took Talyn and their dog on the 1,600 mile drive to Williston.

Travis worked for Montana Mid-West Trucking, which is a sub-contractor for Plains Oil. Their first winter in North Dakota was a tough one; his wife, Tayln, Pacey (Brandon and Braydon live in California) and a dog lived in a 31 foot fifth wheel in the harsh winter of the Midwest. Travis was determined to get his family in a house before the next winter. After working for Montana Mid-West Trucking, he received a job working at Jacam Chemicals hauling chemicals. He worked for Jacam for a little over a year.

Travis was not able to get his family into a home at the start of their second winter in Williston. He had a house built and with Michelle expecting their newly expected edition he could not have picked a better time.

When asked what he loves best about living in Williston and North Dakota Travis said: “I love the cold and the snow. I also love the people. It is one of the few places left with old school thinking and privileged rights of American freedom” for which he fought while serving his country.

Travis misses the life of a surfer and his family in California, but he has found a new home working and living in the Bakken of Western North Dakota and Eastern Montana.

Travis misses the life of a surfer and his family in California, but he has found a new home working and living in the Bakken of Western North Dakota and Eastern Montana.

Travis is one very proud American who still listens to the National Anthem before work every morning and Taps before bedtime each night.

###

Travis Cooksey and Marissa van der Valk were co-workers at Amgen, a pharmaceutical company, at their Thousand Oaks, CA headquarters. Travis worked in the same laboratory with Marissa in which she performed DNA sequencing experiments for the Human Genome Project. Marissa now lives in Basking Ridge, New Jersey and is the daughter of Bob van der Valk , the Senior Editor of the Bakken Oil Business Journal.